Tunnel: a complex system

- 1. Complexity of the system

- 2. Subset "Civil Engineering"

- 3. Subset "Ventilation"

- 4. Subset "Operation equipment"

- 5. Subset "Safety"

- 6. Synthesis

1. Complexity of the system

A tunnel constitutes a "complex system" which is the result of the interaction of very many parameters. These parameters can be gathered by subsets, the principal ones of which are represented in the diagram below (fig. 1).

All these parameters are variable and interactive, within each subset, and between the subsets themselves.

The relative weighting of the parameters and their character varies according to the nature of each tunnel. For example:

- the determining criteria and the weighting of parameters are not the same for an urban tunnel and a mountain tunnel;

- the parameters differ for short and long tunnels, for tunnels passed through by vehicles transporting dangerous goods and for those transporting passenger vehicles only;

- the criteria are not the same for a new-build tunnel or a tunnel to be refurbished or upgraded to put it in conformity with new standards concerning safety.

Note 1: the links are multiple and often reversible - the general concept of the tunnel and the functional section are placed in the centre of the figure. Similar diagrams could be drawn up while placing other factors in the centre of the figure.

Note 2 : the first circle represents "technical fields". Some fields represent multiple aspects:

- safety: regulation - risk analysis - intervention means - requirement of availability,

- geology: geology - geotechnics - structural dimensioning,

- civil works: methods - construction schedule - risks and hazards,

- operation: operation and maintenance (technical aspects),

- costs: construction - operation - daily maintenance - major repairs,

- environment: regulation - diagnosis - impact assessment - treatment and mitigation.

Note 3: the second circle represents the "context" in which the project is to be developed. Some elements represent multiple aspects:

- human environment: sensitivity - urbanisation - presence of buildings or infrastructure,

- natural environment: sensitivity - water - fauna - flora - air quality - landscape,

- nature of the transport: nature and volume of the traffic - typology - types of goods that are transported - etc.

- various external constraints: accesses and particular constraints - climatic conditions - avalanches - stability of the ground - socioeconomic context - etc.

- level of profitability: economic acceptability - capacity of financing - control of the financial costs - general economic and political context in case of concession or Public Private Partnership (PPP).

The design of a new tunnel (or the refurbishment and upgrading of an old tunnel) requires these numerous parameters to be taken into account. The decision tree relating to these parameters is complex, and requires the input of experienced multidisciplinary parties. They must intervene as early as possible, for the following reasons:

- to enable all relevant parameters to be considered from project commencement, and to avoid numerous potential pitfalls noted in projects in progress or in recently completed tunnels. Such errors include the late consideration of the required equipment for operation and safety, and the development of a supervision system without integrating the results of the risks analyses, the emergency response plan or the operation procedures. As a consequence, the tunnel and its systems and equipment for operation and supervision may be inappropriate for safe and reliable operation.

- an early intervention contributes to a better optimisation of the project, both from the perspective of safety as well as for construction and operation costs. Recent examples indicate that transverse optimisations (civil engineering - ventilation - safety evacuation) made at early project stages can contribute about 20% towards cost savings.

Each tunnel is unique and a specific analysis has to be developed, while taking into account all the specific and particular conditions. This analysis is essential to bring suitable answers and to allow:

- optimisation of the project from a technical and financial aspect;

- reduction of the technical, financial and environmental risks;

- guaranteeing the required level of safety for tunnel users.

There is no "magic key solution", and a simple "copy and paste" process is almost always unsuitable.

The design and optimisation of a tunnel require:

- an exhaustive and detailed inventory of all the parameters,

- an analysis of the interactions between parameters,

- the evaluation of the degree of flexibility of each parameter, and if necessary of the sensitivity of each one of them with respect to the required objectives,

- a holistic approach to achieving success, because:

- a purely mathematical approach is not possible, owing to the fact that the "system" is too complex, and there is no single answer;

- too many parameters are still unspecified or variable during the early stages of a project, but essential choices still have to be made;

- the evaluation of the risks, their gravity and their likelihood of occurrence must be taken into account;

- many parameters are interdependent and many interactions are circular.

Several examples are given below showing how it is possible to clarify the complexity, the interactivity, as well as the iterative and "circular" character of the analysis.

These examples are not exhaustive. Their aim is simply to make the reader aware of the issues and make it possible to focus considerations on each specific tunnel.

2. Subset "Civil Engineering"

2.1. Parameters

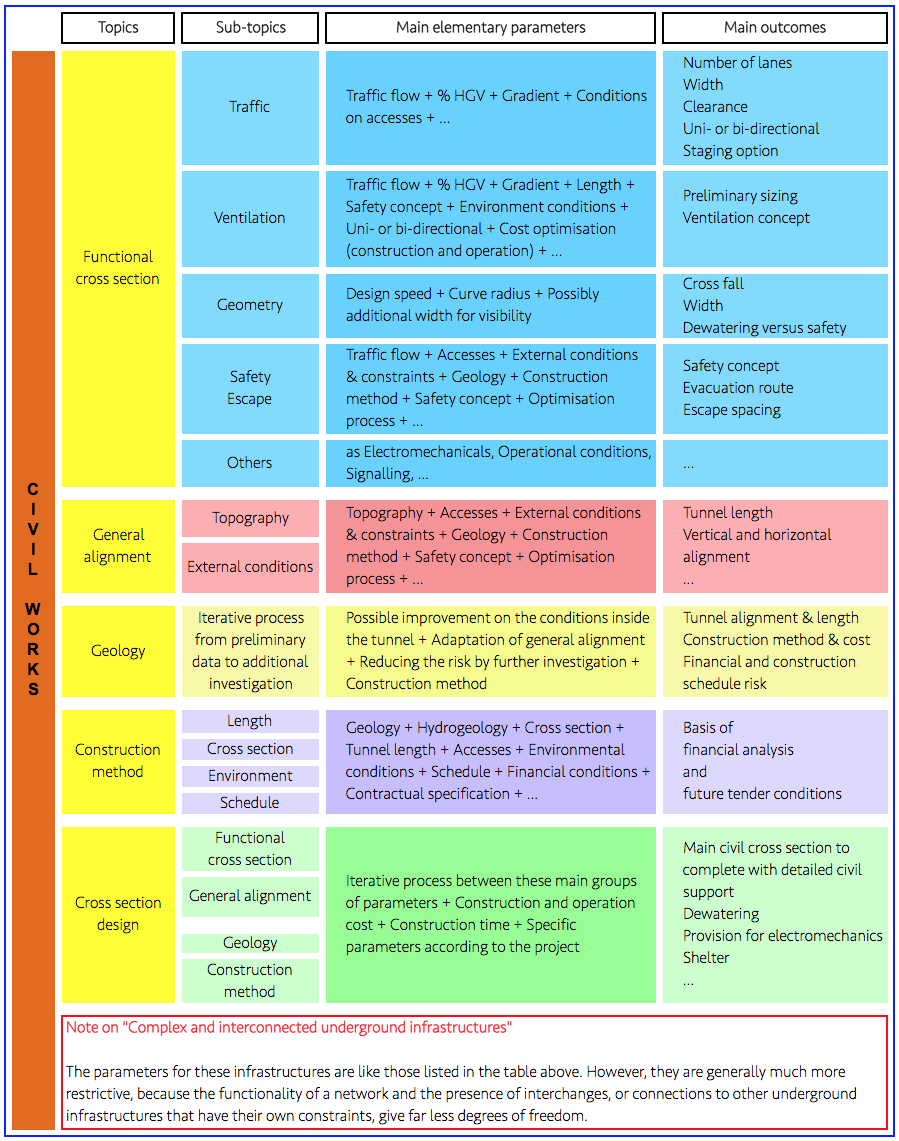

Table 1 below gives an example of the principal parameters concerning the aspects relating to civil engineering:

TABLE 1 : MAIN PARAMETERS ACCORDING TO CIVIL ENGINEERING

The first column of the table indicates the principal sets of parameters,

- The second column of the table indicates the principal subsets of parameters relating to a principal set,

- The third column lists a certain number of elementary parameters relating to a subset. The list is not exhaustive,

- The fourth column of the table indicates by set, or subset, the principal outcomes related to the subset.

2.2. Interactions between parameters

The interactions between parameters are numerous and often connected by circular links taking into account the overlaps between the various parameters.

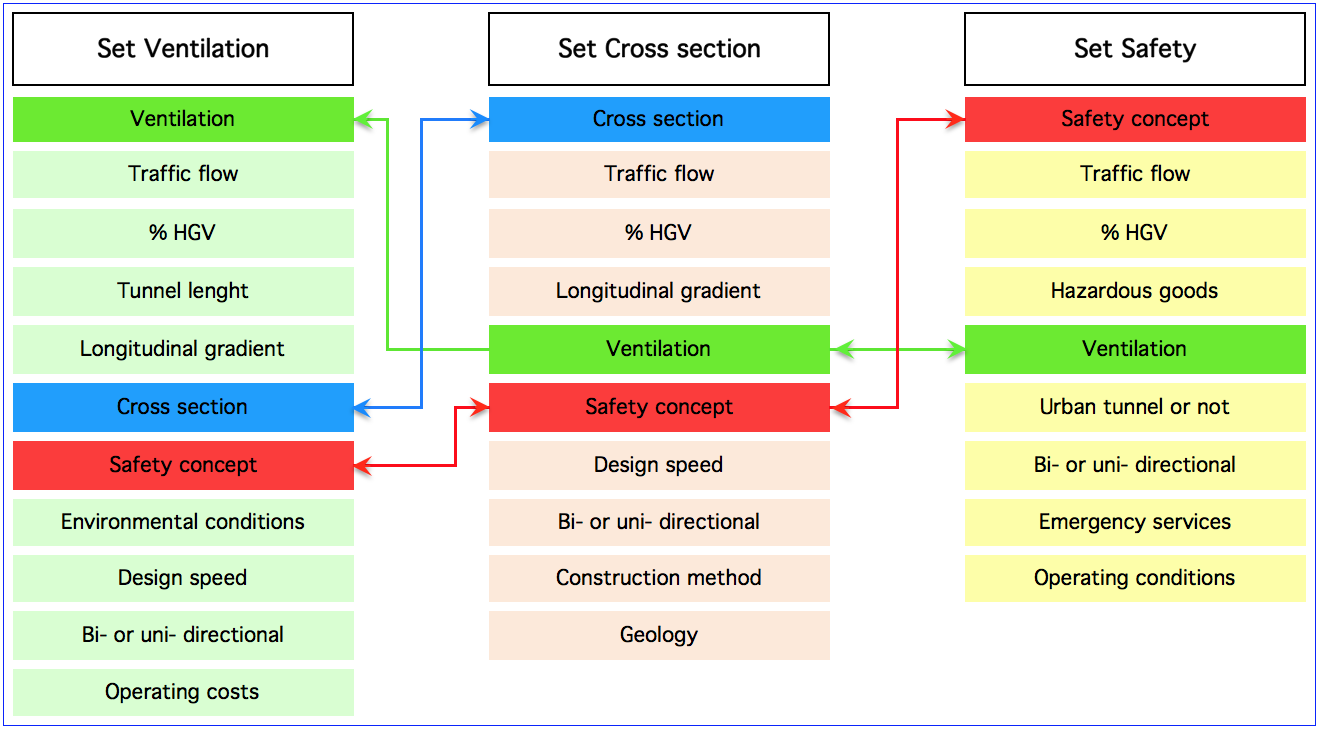

The example below (Table 2) relates to the interactions between ventilation, the cross section, and safety:

- The first column concerns ventilation. The parameters listed in this column are the elementary parameters resulting from table 1 above for the subset "ventilation",

- The second column concerns the cross section. The parameters result from table 1,

- The third column concerns safety.

TABLE 2 : INTERACTIONS BETWEEN PARAMETERS

The table reveals a certain number of parameters common to several columns (see line connectors), which create circular interactions between the various subsets of parameters.

These interactions are linked by complex functions, which make a purely mathematical resolution of the problem nearly impossible. The resolution of the problem requires the definition of a hierarchy between the various parameters, followed by taking into account assumptions for the parameters of higher hierarchy. This hierarchy differs from one project to another, such as for example:

- For a short bored tunnel or a medium-length bored tunnel with one-way traffic, the most probable ventilation system is "longitudinal ventilation". The jet fans fixed in the crown have indeed usually a very low impact on the dimension of the cross-section. This one could thus be dimensioned initially before designing the ventilation, but by taking into account the other determining parameters. The impact of the ventilation on the cross-section will then be checked afterwards,

- Conversely, if the tunnel is very long or the cross-section is rectangular (cut and cover), the ventilation system and its components (section, number and nature of the possible air ducts - dimension of the jet fans if required - etc.) have an essential impact on the cross-section size. The ventilation system will have to be pre-dimensioned at the beginning of the analysis by making preliminary assumptions of the dimension of the cross section. The geometry of the cross-section will then be checked.

The process of resolution is then iterative and based on a first set of assumptions, as the previous examples show. This process requires a large transverse multi-technical experience of the engineers, making it possible to take into account the relevant parameters for the project, to better target the successive iterations, and to guarantee the best optimisation of the project, with the required level of service and safety.

3. Subset "Ventilation"

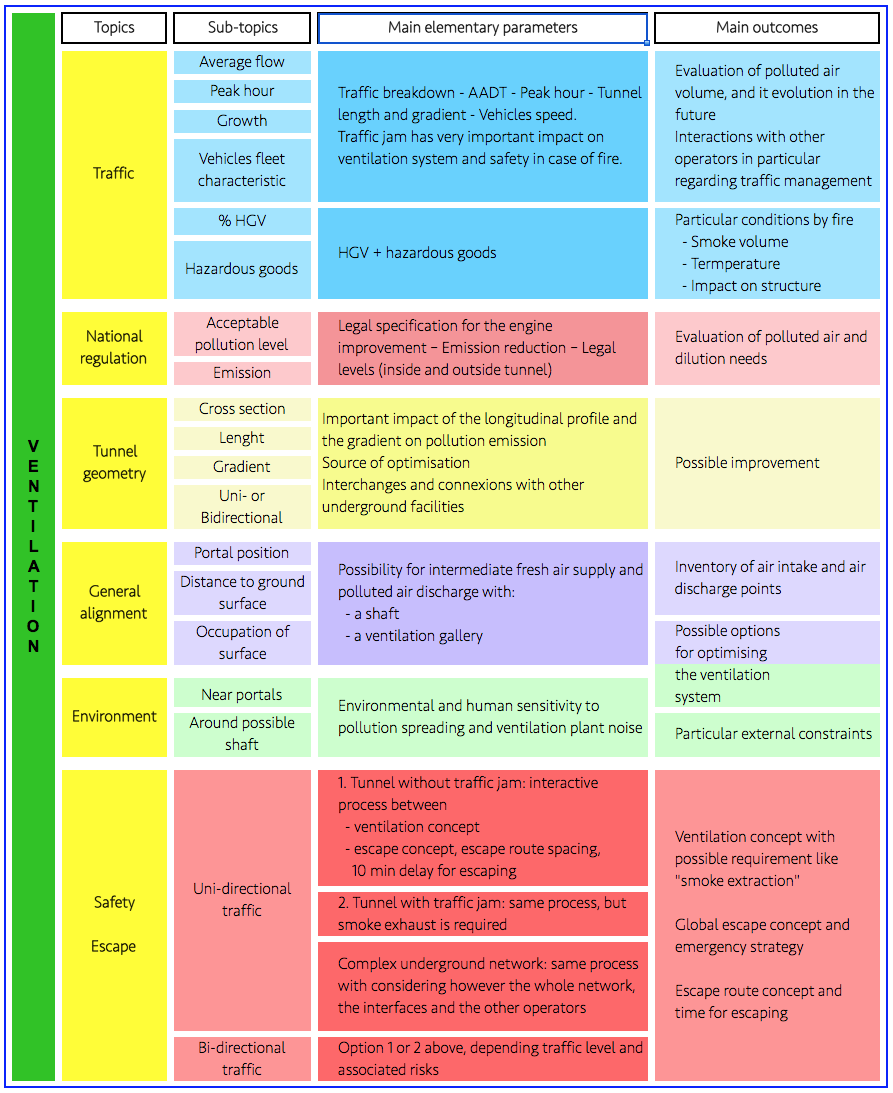

Table 3 below gives an example of the principal parameters concerning the aspects relating to ventilation. This table is not exhaustive.

As for "civil engineering", the interactions between parameters are numerous. They also are subject to circular relations.

The process to solve the problems is similar to the one outlined above for "civil engineering".

Table 3 : Main parameters influencing ventilation

4. Subset "Operation equipment"

They do not constitute fundamental parameters for the definition of the functional section, with the exception of:

- box-outs and sleeves for the passage of cables, pipes for water supply to the fire fighting system,

- signalling, signage for information, safety or police instructions. Signalling may have sometimes (rectangular cut and cover) a very important impact on the geometry (distance between roadway and soffit with a possible impact on the vertical alignment and the tunnel length). This may eventually require a more global optimisation, which may concern the position and/or the design of the interchanges outside the tunnel close to the portals.

"Operation equipment" constitutes on the other hand essential parameters for the dimensioning of the technical buildings at the portals, of underground mechanical and electrical sub-stations, and of all underground technical spaces, or various provisions, recesses and niches. They often require particular arrangements concerning temperature, air conditioning, and air quality.

They also are important parameters in terms of cost: construction, operation and maintenance.

"Operation equipment" constitutes essential parameters regarding tunnel safety. It must be designed, built and maintained in this objective:

- availability and reliability, in particular power supply and distribution, as well as all the communication networks,

- protection against fire of all equipment, in particular of the main power supply cables and the cables of the transmission networks,

- hardiness of the equipment and its components in order to guarantee its life-span, reliability and optimisation of costs: operation and maintenance,

- to facilitate maintenance interventions, their low impact on the traffic conditions, as well as on the safety of the maintenance teams and the users, which requires particular arrangements concerning the design and the accessibility of these facilities,

- integration of the procedures for operation, and the emergency response plan in the design of the supervision system (SCADA), the ergonomics of the man/machine interfaces, and assistance to the operator in particular during an incident.

5. Subset "Safety"

5.1. ASPECTS RELATING TO "SAFETY"

The statistics available in many countries show, quite generally, that the rate of tunnel accidents is notoriously lower than that for the road network in the open air.

Apart from disasters, almost all the accidents recorded and documented in tunnels are mainly due to the following causes:

- Poor design for the geometry: layout (too windy or with reduced characteristics), vertical alignment (significant gradient) and bad coordination between the horizontal and the vertical alignments,

- Too short distances of visibility,

- The behaviour of drivers, an excessive velocity and denials of priority in the exit or merging areas etc.

- An insufficient illumination level and poor identification of the curbs, and thus of the roadway width,

- For tunnels with underground interchanges or connections:

- a bad design of the geometry of the exits and the merging areas, insufficient visibility and legibility – poorly sized exit and merging provisions,

- a bad design of the signalling of the exits and entrances: signalling insufficient, or mispositioned, or illegible,

- collisions at the rear of a traffic jam particularly in the vicinity or on the exit ramps: due to lack of visibility – poor identification of the fluctuating plug-tail – Insufficient information – poor traffic management by the operator – insufficient coordination between the tunnel operator and the surface network operator,

- For the tunnels with bidirectional traffic, additional risks of frontal collisions,

- For the tunnels in mountainous area additional causes due to the formation of stalactites of Ice from the vault or on the walls, of stalagmites or ice formations on the pavement,

Safety aspects are to be broken down into:

- Preventative provisions: These are the ones that day to day allow to reduce the causes of accidents mentioned above. These causes and the resulting provisions are rarely analysed in the "risk and hazard analyses",

- Curative arrangements: These are the ones that are indispensable in the event of disasters or fire (emergency routes - emergency ventilation - organization and access of the emergency teams - etc.). These provisions are necessary and essential to ensure the safety of users in the event of fire, but they have low impact for improving the daily safety inside the tunnel.

Note: Additional information on tunnel accidents is available by following hyperlinks:

- 2016R19EN : Road tunnels: complex underground road networks (§ 4.4.2 for accidents & § 4.4.3 for fires)

- 2017R35EN : Experience with significant incidents in road tunnels (Chapter 3 for accidents – Chapter 4 for fires)

5.2. Concept "Safety”

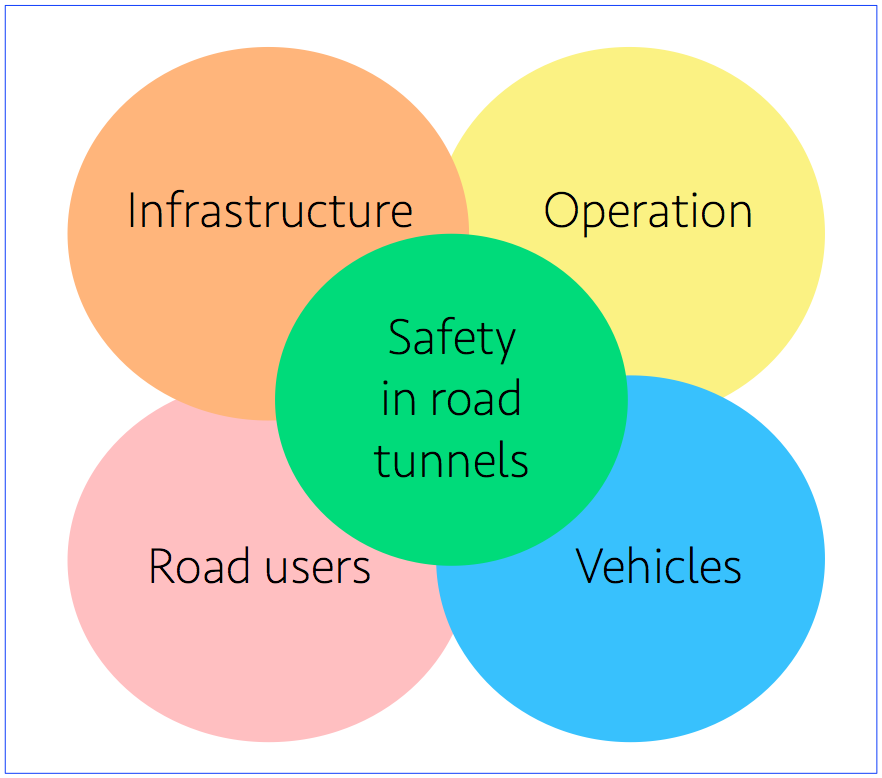

The conditions of safety in a tunnel result from many factors as presented in the Safety book contained in this Manual. It is necessary to take into account all the aspects of the system formed by the infrastructure itself to ensure safety as well as its operation, interventions, vehicles and users (Fig. 2).

The infrastructure is an essential parameter concerning the safety inside the tunnel (preventative and curative provisions), as well as the construction cost. However, one can invest highly in infrastructure without improving conditions of safety if essential provisions are not considered in parallel concerning:

- organisation, human and material means, the procedures of operation and intervention,

- training of operating staff,

- the emergency services' equipment with efficient material and training of their staff,

- communication with users.

5.3. How do these parameters affect a tunnel project?

These parameters relating to safety may affect in a more or less important way a tunnel project. The tables below give some examples.

Note: The four tables below refer to the four principal fields represented in Fig. 2.

- Column 1 indicates the principal infrastructure or actions concerned,

- Column 2 indicates the degree of influence on the tunnel project (civil engineering - ventilation - operating and safety equipment):

Green: no impact,

Yellow: medium impact,

Red: important or major impact. - Column 3 specifies the main reasons or causes of influence.

| INFRASTRUCTURE | IMPACT | COMMENTS |

|---|---|---|

| Visibility – Legibility – Exit and merging conditions on the interchanges and connections with other underground infrastructures | Horizontal and vertical alignment - Coordination layout/vertical profile - Design of the interchanges and connections - Design of the ramps - Exit and merging areas | |

| Escape route | Inside the tunnel - Parallel gallery - Direct external access - Connection between two tubes | |

| Emergency team accesses | From the other tube - Dedicated access - Common with escape route | |

| Volume of people to escape | Size of escape route - Spacing of the connections to the tunnel | |

| Ventilation | Ventilation concept - Inadequacy of pure longitudinal system under certain operating and traffic conditions |

| OPERATION | IMPACT | COMMENTS |

|---|---|---|

| Response plan procedure | Signalling - SCADA - Communication with the users | |

| Intervention rescue team | Size of the portal building - Eventual underground facilities - Specific tool - Size of water tanks | |

| Team training | Particular external facilities - Special software |

| VEHICLES | IMPACT | COMMENTS |

|---|---|---|

| Traffic flow average and peak hour | Number of lanes - Ventilation concept and sizing | |

| Transport of dangerous goods | Ventilation impact - Particular drainage for hazardous goods spillage - Operating procedures with particular convoy with fire brigade accompanying --> parking facilities and staff | |

| State of the vehicle | In particular condition, size control and overheat control before entering --> gantry heat control + parking + staff | |

| Restriction of particular vehicle categories | Example: urban tunnel dedicated to light vehicles - Tunnel size, ventilation escape routes |

| ROAD USERS | IMPACT | COMMENTS |

|---|---|---|

| Information | Leaflet distributed before entering - TV information campaign | |

| "Live" communication | Signalling, VMS, radio broadcast, traffic lights, impact on cross section, mechanical and electrical equipment, SCADA, sometimes remote barriers | |

| Teaching | Driving school (in several European countries) | |

| Guidance to escape routes | Signalling - Handrail - Flash - Noise - Impact on mechanical and electrical equipment and SCADA | |

| Speed and spacing between vehicles control | Radar and spacing detectors - Impact on mechanical and electrical equipment and SCADA |

6. Synthesis

A tunnel is a "complex system" which means in particular that:

- approaching the design of a tunnel from the point of view of only the alignment, the geology or the civil engineering, leads to serious design deficiencies, which are likely to make the tunnel less safe (possibly even dangerous) and difficult to operate (perhaps impossible to be operated under reasonable conditions).

- in the same way, to approach the design of a tunnel from the point of view of only the operating equipment without integrating an upstream analysis of risks and safety, intervention and operation, will also lead to deficiencies that will very quickly appear as soon as the tunnel is open to traffic,

- not taking into account, from the preliminary design stage, all the objectives and constraints relating to the operation and to the maintenance, will inevitably lead to increased operational costs and to reduced overall reliability.

Partial treatment of problems is unfortunately still rather frequent, due to lack of sufficient "tunnel culture" of the various actors involved in the design.

Control of this complex system is difficult but essential in order to:

- find the appropriate solution to each problem,

- ensure the users have an essential level of safety, and to offer them a service of quality and good comfort.

In a parallel way the control of this complex system very often contributes to the technical and economical optimisation of the project, by a clear and early definition of the functions to be ensured and by using a value engineering process.

Taking into account, from the start of the project, the major issues relative to:

- horizontal and vertical alignments, geology, civil engineering construction provisions and methods,

- ventilation,

- safety (by a preliminary analysis of risks and danger and a preliminary emergency plan),

- operation and maintenance conditions,

constitutes an effective approach to solving this complex equation.

The definition of the “tunnel function", as well as the "preliminary risks and dangers analysis" are often neglected or superficially treated. They are, however, an essential and indispensable "tool" for the technical, economical and safe optimization of a tunnel.

The " preliminary risks and dangers analysis " should not be confined to tunnel fires and constructive and operational provisions to minimize risks. It must also consider (which is rarely the case) the daily safety conditions to reduce the likelihood of incidents and their severity. This implies an analysis of the horizontal and vertical alignments, of the geometry of the ramps of the underground connections, of the visibility, of the likelihood of traffic congestion. This analysis must be done during the design of the alignment, while it is then still possible to improve the project in order to reduce the risk of incidents.