Water impact

The impact of road infrastructure on water quality can be very significant during both normal operation (leaking of hydrocarbon products, tyre wear, etc.) and accidental situations (spilling of large quantities of pollutants).

The existence of a tunnel does not change the problem very much. As on any road, there is a need for water treatment (decanting, removal of pollutants) before releasing it into the environment. A few tunnel-specific facts should however be taken into account when designing water management systems. First, tunnels need to be cleaned on a regular basis, as often as every month for heavily trafficked urban tunnels. This generates large amounts of waste water containing cleaning products. Second, tunnels in which dangerous goods transports are allowed are generally equipped with specific gutters in order to limit the spread of flammable liquids on the pavement. If an accidental spill occurs, the flow rate of pollutant liquid in these gutters may be higher than what is encountered on a regular road surface, and the water management system should be capable of coping with these flow rates.

Very challenging issues related to water may be encountered during the construction phase in sensitive environments, for example regarding the turbidity of the construction site effluent. Appropriate measures should then be taken. In some cases, they represent significant constraints and cost for the construction works. Tunnel construction and related issues are outside the scope of the PIARC committee dedicated to road tunnel operation. The reader is therefore encouraged to consult ITA recommendations for further details.

Water impact is another aspect that has to be analysed during the life cycle of an infrastructure as tunnel.

Most of the impact of tunnels on water (and water on tunnels) happens during their construction, but some of the impacts remain for a long time and can become a hindrance to the tunnel operation and maintenance. Due attention must be given to these processes during the tunnel planning and design stages, in order to avoid adverse, and costly, consequences. Detailed investigation of surface and subsurface hydrology should take place before and during construction. The least damaging route (and structural elements) should be chosen to obtain minimum interruption and alteration of hydrological patterns and processes.

Theoretically, tunnels can be: impermeable (allowing no ingress of water and developing the full water pressure on the lining), permeable or semi-permeable (allowing some ingress of water and avoiding the development of full water pressure on the lining). In practice most tunnels are permeable during their construction and impermeable or semi-permeable during their operation. As a general rule water ingress into road tunnels are normally not accepted as it may have severe impact on the tunnel structure and in special cases can cause severe deformations, displacements, settlements and unwanted stresses leading to deterioration and in worst case collapse of tunnel walls and ceiling (bursting and squeezing of bare rock as well). For mechanical and electrical installations it may impact their functionality and lifetime expectation.

Minor water ingress is tolerated if it can be completely controlled. This covers tunnels located in specific rural areas and with extremely low traffic. This has been done in several locations in the period 1970 to 2000. In recent years, rock tunnels have been constructed a with semi- or full inner-lining due to experience with tunnel collapses etc.. As a general rule (see national and international standards, codes etc.), all tunnels nowadays are designed with waterproofing systems to be delivered as completely waterproofed tunnels.

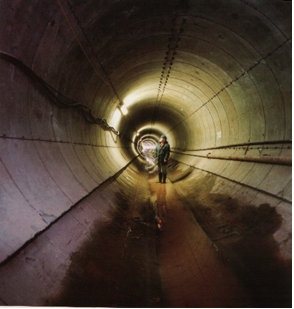

In unlined tunnels (or with a permeable lining), water ingress can be important. Fig. 2 shows water flowing through a permeable basalt layer in Canada.

The drying up of groundwater levels caused by the manner of building infrastructure is a topic which is becoming more and more important. The effect usually does not finish during tunnel operation, and the groundwater original levels almost invariably go down, with an irreversible impact on water supply wells.

The water entering a tunnel can dissolve the free lime hydroxide in the concrete lining, becoming more alkaline and releasing solid deposits in the drainage systems. This effect is more frequent in old tunnels with out-dated drainage systems. Fig. 3 shows drainage water flowing and lime calcium hydroxyls precipitating in a concrete lined tunnel. Fig. 4 shows a similar effect in a construction joint.