Road Tunnels Manual

Road Tunnels Manual

The fire resistance of a structure can be characterised by the time which elapses between the start of a fire and the time when the structure does not ensure its function any longer, due to unacceptable deformation or collapse.

Chapter 7 "Design Criteria for Structure Resistance to Fire" of technical report 2007 05.16.B "Systems and Equipment for Fire and Smoke Control in Road Tunnels" summarises the objectives of structural fire resistance in tunnels as follows:

A supplementary objective is to limit the time during which traffic will be disrupted due to the repairs after a fire.

An overview of the subject was published in Chapter VII.4 "Fire resistance of structures" of technical report 1999 05.05.B "Fire and Smoke Control in Tunnels".

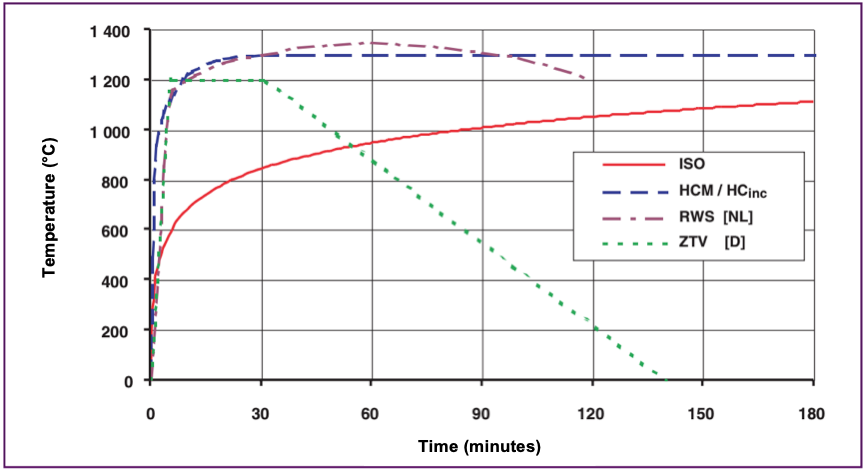

The fire resistance of structures is described in relation to different time-temperature curves. Figure 1 shows the ISO 834 curve, the Dutch RWS curve, German ZTV curve and a French 'increased' Hydrocarbon curve, HCinc, in which the temperatures are multiplied by a factor of 1300/1100 from the basic Hydrocarbon (HC) curve of Eurocode 1 Part 2-2.

Design criteria for resistance to fire in tunnels have been agreed between the World Road Association (PIARC) and the International Tunnelling Association, as presented in the Routes/Roads article "PIARC Design Criteria for Resistance to Fire for Road Tunnel Structures" (2004), and published as a PIARC recommendation in Chapter 7 "Design Criteria for Structure Resistance to Fire" of technical report 2007 05.16.B.

A summary of the proposals is presented in Table 1. On the basis of the time-temperature curves presented in figure 1 above, table 1 identifies the curve to be chosen and the duration during which this curve must be respected. This information is given for different types of main structures and secondary structures and for two types of traffic: cars/vans and lorries/tankers.

|

Traffic Type |

Main Structure |

Secondary Structures (4) |

||||||

|---|---|---|---|---|---|---|---|---|

| - | Immersed or Under/Inside Superstructure |

Tunnel in Unstable Ground | Tunnel in Stable Ground | Cut & Cover | Air Ducts (5) | Emergency Exits to Open Air |

Emergency Exits to Other Tube |

Shelters (6) |

| Cars Vans |

ISO 60 min |

ISO 60 min |

See note (2) | See note (2) | ISO 60 min |

ISO 30 min |

ISO 60 min |

ISO 60 min |

| Lorries Tankers |

RWS/HCinc 120 min (1) |

RWS/HCinc 120 min (1) |

See note (3) | See note (3) | ISO 120 min |

ISO 30 min |

RWS/HCinc 120 min |

RWS/HCinc 120 min (7) |

Notes

(1) 180 min may be required for very heavy traffic density of lorries carrying combustible goods.

(2) Safety is not a criterion and does not require any fire resistance (other than avoiding progressive collapse). Taking into account other objectives may lead to the following requirements:

(3) Safety is not a criterion and does not require any fire resistance (other than avoiding progressive collapse). Taking into account other objectives may lead to the following requirements:

(4) Other secondary structures: should be defined on a project-specific basis.

(5) In case of transverse ventilation.

(6) Shelters should be connected to the open air.

(7) A longer time may be considered if there is a very heavy volume of lorries carrying combustible goods and evacuation from the shelters is not possible within 120 min.

The consequences of failure will influence the requirements for fire resistance. This depends on the type of tunnel. In an immersed tunnel, for example, a local collapse can cause the whole tunnel to be flooded whereas local collapse in a cut-and-cover tunnel may have very limited consequences. A basic requirement is that progressive collapse must be prevented and vital longitudinal systems, such as an electrical supply or communication cables, are not cut off.

The materials used in tunnel structures involve different precautions for fire protection. Section VII.3 "Fire reaction of materials" of the report 1999 05.05.B "Fire and Smoke Control in Tunnels" discusses the characteristics of rock tunnel linings versus reinforced concrete. The intensity of the heat generated during a major fire may cause reinforced concrete to lose its supporting function. The role of insulation using fire-resistant protection can be applied to prevent early damage to the structure. The fire resistance of the total construction (type and depth of reinforcement/prestressing, additional protection, etc.) needs to be considered.

Spalling of concrete is caused by differences in temperature and expansion. It causes a danger for the reinforcement which is more easily exposed to high temperatures. It will generally not be a danger for evacuating people, but it may be dangerous for firemen. Various types of fire-resistant protection can be used to reduce the risk and the effects of spalling, although it can never be completely prevented due to the high temperatures that may occur.

Spalling of concrete is caused by differences in temperature and expansion. It causes a danger for the reinforcement which is more easily exposed to high temperatures. It will generally not be a danger for evacuating people, but it may be dangerous for firemen. Various types of fire-resistant protection can be used to reduce the risk and the effects of spalling, although it can never be completely prevented due to the high temperatures that may occur.

Attention must be given to the fire resistance of the ventilation system so that its design performance is not impaired by failure. Therefore it is necessary to examine the consequences of a local collapse of a duct in case of fire.

Escape routes are only used during the first phase of the fire for the escape of trapped people. It must be possible to use such routes for a period of at least 30 minutes. In cases where these routes are also used by the rescue and fire teams, the period may be longer.

To avoid fire spreading into an adjacent tube or escape route, emergency doors, emergency recesses and other equipment located between two traffic tubes, should remain intact during a specified period of time. The whole emergency door and surrounding construction, including the door frame, should resist fire for at least a 30 minute fire exposure. For a door between two traffic tubes, a much longer resistance is required, for example 1 to 2 hours.