Road Tunnels Manual

Road Tunnels Manual

The ventilation design process basically includes the choice of the type of ventilation system, the computation of the minimum acceptable capacity of the system in terms of thrust and/or flow rates, the design of the ventilation network and the selection of appropriate ventilation equipment, which should meet a number of specifications, including resistance to fire and acoustic performance.

The choice and design of a ventilation system depends on these main factors:

The page on "Ventilation principles" provides general information on the different types of ventilation systems that can be found in road tunnels.

A natural ventilation system can be very effective for the dilution of pollutants (especially for unidirectional tunnels), but it is not possible to rely upon natural ventilation for safety purposes for tunnels over a few hundred meters in length. Because of the number of contradictory design parameters, it is not possible to express universal recommendations about the limits of the natural ventilation.

In most countries, the need for a mechanical ventilation system during normal operation is assessed considering the length of the tunnel and the traffic type (bidirectional or unidirectional) and conditions (possibility of congestion). The same factors determine the requirements for ventilation in emergency situations, especially fire. The presence of other equipment or facilities, emergency exits for example, should also be taken into account.

Generally speaking, two types of ventilation strategies can be found:

In order to decide between longitudinal ventilation (LV) and transverse ventilation (STV/TV) for a given tunnel situation, these are some of the arguments:

Further information on the impact of tunnel ventilation in the overall operational costs and energy consumption can be found in the PIARC report 1999 05.06 Road Tunnels: Reduction of operating costs

Nowadays, the choice between the different ventilation system choices is mostly guided by fire safety considerations although environmental aspects are gaining importance during the decision taking process. In sections V.7 “Recommendations on longitudinal ventilation” and V.8 “Recommendations on transverse and semi-transverse ventilation” of the 1999 PIARC report 1999 05.05 "Fire and Smoke Control", relevant design criteria and description of the main limitations can be found.

PIARC report 2007 05.16 "Systems and equipment for fire and smoke control in road tunnels" analysed additional aspects related to this type of systems. Thus, section "4.4 Longitudinal ventilation" includes criteria and guidelines for the design and testing of this type of system, including considerations regarding the sound levels to be reached in the tunnel environment ("4.4.2 Sound Impact of Jet Fans in a Tunnel").

Furthermore, the design of ventilation systems has to cover other project-wide topics including availability, durability, maintainability or reliability. Some guidance and considerations on life cycle cost for ventilation systems can be found in the PIARC report 2012 R14 "Life Cycle Aspects of Electrical Road Tunnel Equipment".

The section on "Ventilation during normal operation" of the page on "Ventilation principles" presents some general background information of interest in relation to normal operation in road tunnels.

The design of a road tunnel ventilation system must consider fresh-air demand for maintaining in-tunnel air quality during normal and congested traffic operations and the control of smoke and hot gases in case of fire. The ventilation capacity to manage a fire incident frequently drives the ventilation sizing in highway and non-urban tunnels. Nevertheless, the fresh-air requirement for dilution during normal and congested operation, or special environmental constraints, can be dominant in tunnels with high traffic volumes and frequent congested traffic.

The ventilation capacity for normal operation is defined by the air demand required to dilute vehicle emissions to maintain allowable in-tunnel air quality values.

The fresh-air demand (airflow rate) is determined by the allowable increase of emission concentrations within the airflow. Air enters the tunnel environment with ambient pollutant concentrations. As this air moves through the tunnel environment, tailpipe emissions increase the pollutant concentrations. The vitiated air must then be diluted within the tunnel environment prior to reaching admissible pollutant limits. Emission concentrations within the tunnel are the product of the emission rates and the inverse of the airflow.

The required amount of fresh air for a given traffic situation in the tunnel depends on the number of cars in the tunnel, the average emission per car in this traffic and the admissible concentration for this particular emission.

Several PIARC reports dealing with the topic of design and dimensioning of tunnel ventilation for normal operation have been published during the last decades. The PIARC report 1996 05.02 “Road Tunnels: Emissions, Environment, Ventilation" defined a method for the calculation of the fresh-air demand and to provide emission rates for tunnel ventilation design, and in addition some general and specific information which may be useful when designing a longitudinal or semi-transverse ventilation system were provided.

However, due to the continual renewal of the vehicle fleet, a steady tightening of emission laws and the introduction of alternative propulsion systems (hybrid vehicles, electric cars, etc.) design emissions data required constant updating. As a result, new versions of the 1996 report were published in 2004, 2012 and the latest in 2019 (see PIARC report 2019 R02 “Vehicle emissions and air demand for ventilation”), which provide new methods for the calculation of the fresh-air demand and emission rates on an international basis.

The emission rate is a function of several factors including:

A detailed description of the method for the calculation of the emission generation rate (section 5) and the latest version of the database can be found in the 2019 emissions report. For practical purposes an electronic format excel sheet containing the emissions data can be downloaded from the PIARC virtual library.

The section on fire scenarios of the page on "Ventilation principles" presents some general background information of interest in relation to emergency scenarios in road tunnels.

The ventilation capacity required by normal operation may not be sufficient to fulfil the requirements of smoke handling. In addition, the airflow required to achieve a sufficient control of the smoke depends on the fire size.

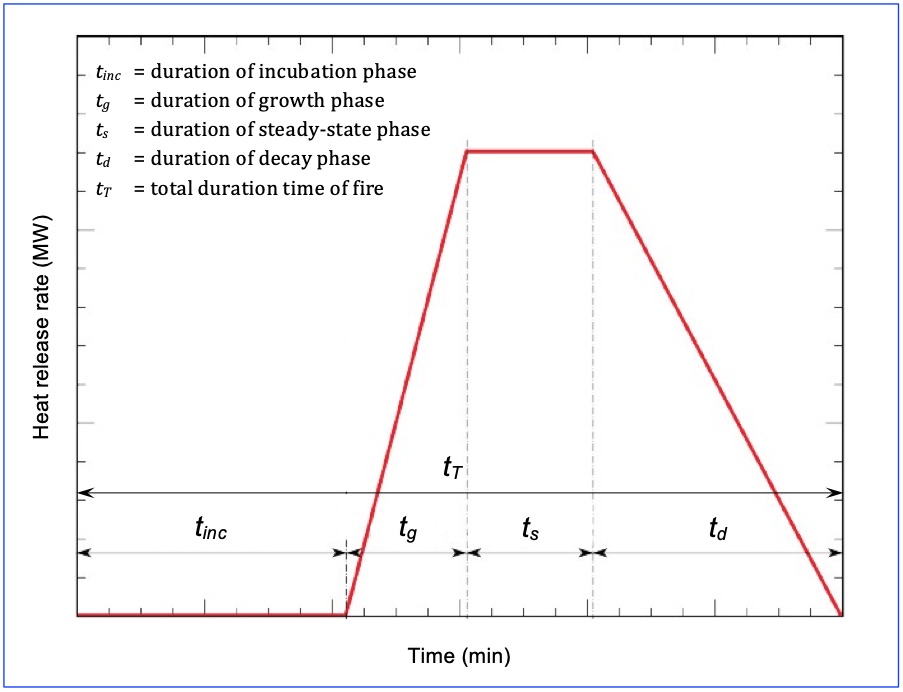

With the objective of defining the ventilation capacity, the design fire (defined as a Heat Release Rate or HRR, in MW, as a function of time) provides the fire characteristics that are used to establish the sizing of equipment in tunnels and the scenarios to consider when developing emergency response plans.

The choice of a design fire depends on the type of traffic allowed in the tunnel. Following the 30 MW design fire peak value recommended in the PIARC report 1999 05.05 "Fire and Smoke Control", the PIARC report 2007 05.16 "Systems and equipment for fire and smoke control” restated the previously established peak heat release rates for different types of vehicles and also discussed the fire growth in the context of emergency exits.

Lately, the PIARC report 2017 R01 "Design fire characteristics for road tunnels" gave some direction to the choice of a design fire from a life-safety perspective. The report provides information on tests and the events that have brought the topic into question and also summarises the criteria for the design fire that are currently adopted in different countries.

In addition, the report presents the different approaches currently adopted in most countries for the choice of design fires in road tunnels.

Prescriptive design involves the application of a design fire given by a code or standards which may vary depending on the traffic type, density and tunnel length and location, and the designer or authority would choose the appropriate value for a given case. Section 2.1 "Summary of practices adopted in different countries" of the PIARC Report 2017 R01 "Design fire characteristics for road tunnels" summarizes the typical design-fire assumptions used in different countries.

In a performance-based approach a process of design assessment will establish levels of risk that are acceptable. The starting point may be the prescriptive values adopted, modified in the light of mitigation measures and acceptable risk levels.

Between these two approaches, there are intermediate options that allow a degree of performance-based design on the basis of prescriptive guidance.

The influence of Fixed Fire fighting systems in the definition and choice of a design fire is discussed in the PIARC report 2016 R03 "Fixed Fire Fighting systems in road tunnels: Current practices and recommendations".

As a conclusion, an exact universal design fire cannot be specified; indeed to do so would be inconsistent with the known variability and probability of differing fire sizes in tunnels. However, once it is defined for each specific case, the ventilation capacity for fire scenarios can be accordingly evaluated, with different considerations depending on the type of ventilation system.

Longitudinal ventilation

Longitudinal ventilation systems induce a longitudinal flow along the axis of the tunnel, and this provides an efficient smoke-management system as long as the tunnel is occupied only on one side of the fire, thus assuming that traffic downstream can proceed out of the tunnel. Smoke is blown toward the unoccupied side, so that egress can be carried out in the upwind direction.

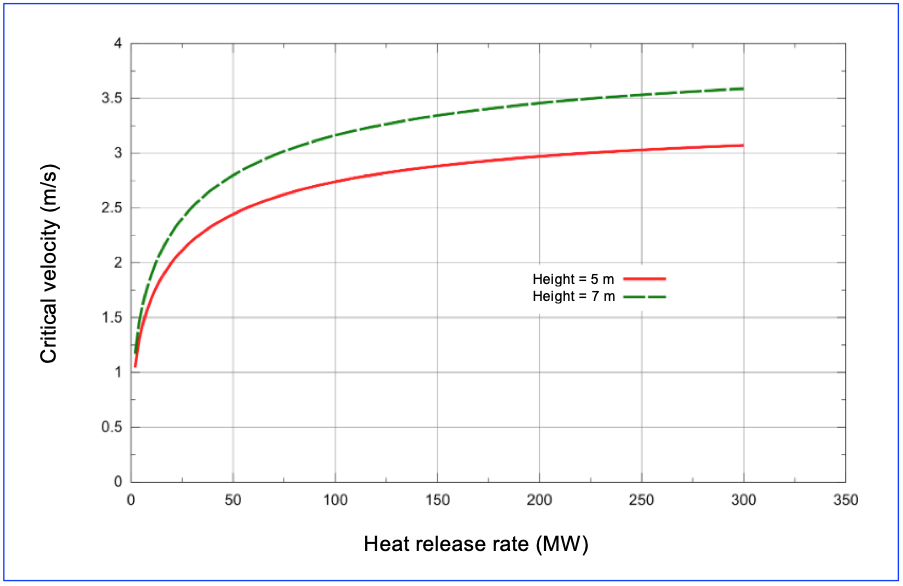

This is achieved when the longitudinal ventilation is conducted at a velocity of at least the critical velocity. Too low a velocity would result in smoke propagation upstream of the fire (i.e. back-layering).

Transverse ventilation

Recent developments in semi-transverse smoke extraction, aim at limiting the smoke spread on both sides of the fire. This enables egress away from the fire on either side. This method is essential in case of rescue from a fire in a tunnel with bi-directional traffic or traffic congestion. Ideally, the extraction system should cause air to flow in the traffic space, towards the fire on both sides, as shown in the figure. This confines the smoke region and increases the efficiency of extraction.

Some systems employ remotely controlled dampers that enable point extraction of smoke near to the fire. The construction costs for an extract system are higher than for longitudinal systems and since the required duct size increases with the heat-release rate, a larger design fire has an impact on the resulting investment costs.

Additional information on the implications on the design fire of the smoke-management can be found in chapter 3 of the PIARC report 2017 R01 "Design fire characteristics for road tunnels".

Once the type of ventilation system has been chosen and the ventilation capacity (in terms of airflow required) is determined, dimensioning of tunnel ventilation must allow the definition of the equipment precisely to deliver the required ventilation capacity both for normal operation and fire scenarios.

In general, ventilation sizing for longitudinal ventilation consist of the calculation of the required thrust for the jet fans or Saccardo nozzles, while for transverse ventilation the size of the exhaust and/or supply ducts and the air flow, pressure and electrical power of the associated axial or centrifugal fans must be estimated.

More detailed information on the ventilation equipment characteristics can be found on the page "Tunnel Ventilation System" included on the general page on "Equipment and systems".

The following general and specific information may be useful when dimensioning a longitudinal or semi-transverse ventilation system.

Longitudinal ventilation

With the help of an air-jet placed in the tunnel air column, the air flow resistance can be overcome by converting the jet momentum into static pressure. The air jets can be placed at the tunnel entrance (Saccardo), blowing outside air into the tunnel or as ducted fans along the tunnel, each one accelerating part of the tunnel air flow.

Basic formulae were given in section IV.2 "Longitudinal ventilation" of the PIARC report 1996 05.02 “Road Tunnels: Emissions, Environment, Ventilation” for sizing jet fan systems (thrust and number) used in longitudinal ventilation for normal operation, considering many factors such as the vehicle piston effect, meteorological counterpressure, resistance of the walls, etc. Considerations in jet fan design included the influence of fire on the jet fan system, the meteorological effects at tunnel portals (mainly wind), the optimal placement of the fans, the efficiency of the fans, and the sound levels created by the fan system.

PIARC report 2007 05.16 "Systems and equipment for fire and smoke control" included additional considerations to evaluate the influence of fire on a jet fan system, providing further recommendations for fan distribution along the tunnel. Of particular interest for the dimensioning of longitudinal ventilation systems is the example calculation in section 12.3.3. "Jet Fan calculation procedure", which provides detailed information on the procedure to size longitudinal ventilation systems.

Transverse ventilation

To size a transverse ventilation system for fire scenarios, two aspects must be considered:

Basic formulae are given in section IV.3 "Semi-transverse ventilation" of the PIARC report 1996 05.02 “Road Tunnels: Emissions, Environment, Ventilation” for estimating the total pressure loss along the distribution duct and ventilation stations during normal operation.

The PIARC report 1999 05.05 "Fire and Smoke Control", provides a table (see table 2.4.3) and the relevant relationship between heat release and smoke flow rates. In addition, in section V.8 “Recommendations on transverse and semi-transverse ventilation" criteria are provided for the sizing of ventilation systems of this type, including extraction capacity, the differences between distributed or concentrated extraction systems and the influence of the fresh air supply on the behaviour of the fumes.

PIARC report 2007 05.16 "Systems and equipment for fire and smoke control" included additional considerations for the choice of the ventilation equipment (see section 12.4 “smoke dampers”).

In comparison with conventional tunnels, specific design criteria that might have a significant impact on the design of the ventilation systems have to be considered in the case of urban and complex network tunnels.

The design of urban and complex tunnel ventilation systems strongly depends, among others, on the following factors:

Further information on this topic can be found in chapter 6 of the PIARC report 2016 R19 “Road Tunnels: Complex underground road networks” and in the PIARC report 2008 R15 “Urban road tunnels - Recommendations to managers and operating bodies for design, management, operation and maintenance”.