Road Tunnels Manual

Road Tunnels Manual

As a consequence of the major disasters in road tunnels (Mont Blanc tunnel fire in 1999, Tauern tunnel fire in 1999 or Gotthard tunnel fire in 2001), specific attention was turned to the safety standards of existing tunnels. Existing tunnels require specific approaches and tools to identify and evaluate the need for safety upgrade programmes. Substantial research and studies followed these major tunnel fire incidents, demonstrating that many existing road tunnels require additional and specific means to ensure a safe environment for users. Even where previous improvement programmes have been carried out, existing tunnels may not be in line with the current safety standards because of upgrading of regulations in the meantime.

These incidents and subsequent studies have raised awareness of tunnel risks amongst individuals involved in road tunnels, from designers and operators to authorities' representatives. It has become clear that safety upgrading is not only a matter of improving the structure and/or equipment, but that there is also, and sometimes mainly, a strong need to clarify the organisation of safety management and to adapt associated procedures.

In the assessment of safety in existing tunnels, special attention should be paid to changes in the tunnel environment (traffic volume and composition, dangerous goods transport, construction works in the surrounding area, etc) which may also induce the requirement for upgrading measures.

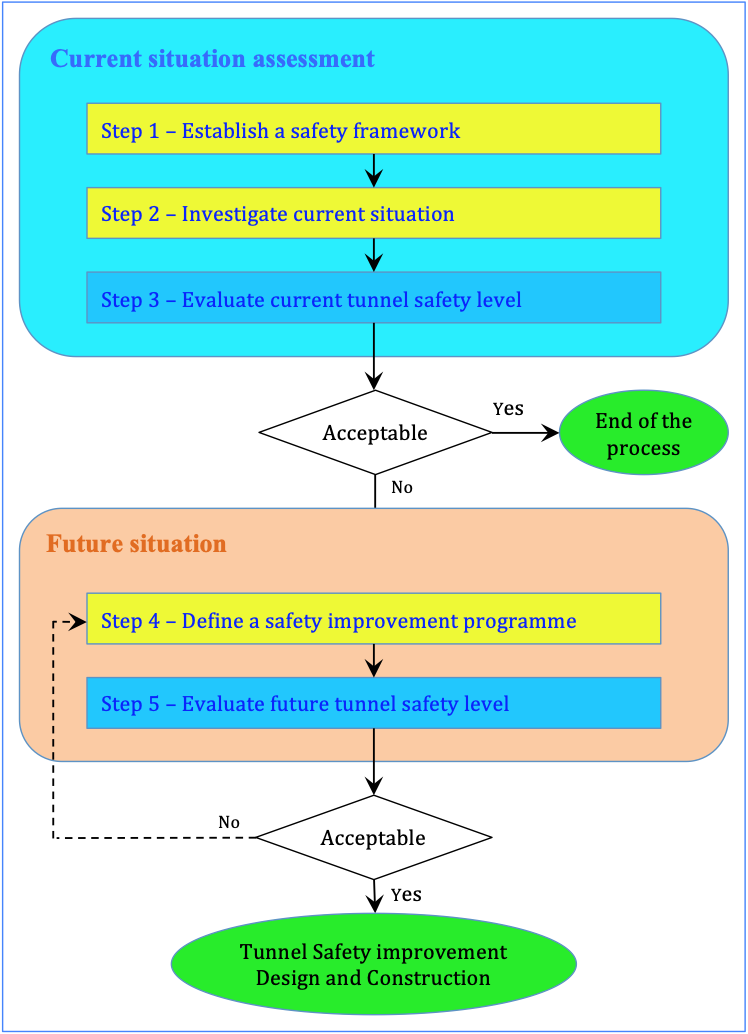

A structured approach for assessing and preparing refurbishment programmes is proposed with two main tasks:

The multistage process for the preparation of a tailor-made renovation programme for a tunnel in operation can be summarised in the flowchart below. It describes the functional links between the various steps and their respective outputs.

In detail, the content of each step is to be adapted to the specific conditions of the individual tunnel, its environment, and of course specific local practice.

Depending on the tunnel situation, the process can be stopped after step 3 with a simple comparison to the reference state if the analysis is demonstrating that the required safety level is already achieved. Indeed, for tunnels already renovated, step 3 can be the end of the process. If not, step 3 may highlight urgent mitigation measures which can be implemented immediately to improve the tunnel safety level with non-substantial actions such as closure barriers, signalling or traffic control measures. In some cases, such measures may be sufficient to obtain the required safety level.

If more substantial works are required, temporary modifications of the operating conditions may be a useful tool for a temporary increase in the tunnel safety level, if necessary.

The preparation of renovation works for a tunnel in operation is an iterative process, as it is a combination of technical issues, safety measures, cost implications and works phasing constraints. This is why step 4 and 5 can be refined several times to obtain an adapted refurbishment programme taking into account all relevant parameters which may influence the decision. Design activities can start after step 5.

Report 2012R20 "Assessing and improving Safety in Existing Road Tunnels" provides guidelines for each step within this process, up to the definition of an improvement programme.

Typical weak points (safety deficiencies) in existing tunnels are presented in Appendix A of this report. Additionally, case studies of existing tunnels in Europe demonstrate the strategy adopted for renovation works and upgrading measures implemented (Appendix B).