Increasingly, road designers select tunnels as a good alternative, considering the ability of road tunnels to reduce some components of the environmental impact such as visual intrusion of infrastructures and noise pollution. Nevertheless some impacts remain or are even increased by such a choice. Despite all policy efforts to try to control and even reduce traffic, it is expected that traffic will increase during the next decades; so environmental issues linked to road traffic need to be considered.

The PIARC tunnel committee specifically investigated air pollution phenomena in depth, considering:

In fact, when considering air pollution, choices concerning the type of ventilation system determine the basis for designing the locations and flow rates of exhaust air; the operation regime and air quality settings for the ventilation control can often be more effective in delivering the required targets for local pollutant concentration than the selection of more complex ventilation systems.

Road traffic and (consequently) vehicle emissions constitute a serious environmental concern particularly in confined spaces such as tunnels. These emissions are characterized by the presence of various pollutants, which, at high concentrations, can cause adverse effects and consequences. The PIARC tunnel committee traditionally assesses vehicle-induced emissions and air quality inside tunnels. To this purpose, common modelling theories are reviewed, relevant air quality standards are defined and existing conditions are characterized. Measured and simulated pollutant concentrations are compared with air quality standards. Finally, mitigation measures are proposed to ensure proper air quality management inside the tunnel. Additional information on this aspect can be found in PIARC technical report 2019R02EN: “Road Tunnels: Vehicle Emissions and Air Demand for Ventilation” .

Tunnel air temperature may be a significant environmental issue in very long tunnels due to the heat that emanates from vehicles, and in tropical countries where the ambient temperature is already high outside the tunnel. In such cases, tunnel users such as motorcyclists and motorists in naturally ventilated vehicles may be subjected to unacceptable air temperature inside the tunnel. Solutions to excessive tunnel air temperatures have been sought through mechanical ventilation and also through the spraying of water into the tunnels, i.e. using the latent heat of evaporation to cool the tunnel air.

Tunnel emissions affect the air quality within a relative short distance from the points where emissions are dispersed, however the adjacent road network influences the environment in a broader area. Accordingly the air quality implications of tunnels should be examined in the context of the outside road network of which they are a part (see page on Tunnel impact on outside air quality).

Other important environmental issues are noise and vibration. Noise pollution can arise during the phase of construction causing environmental hazards, because a high noise level is often generated. In addition, high volumes of vehicles during normal traffic operation can generate large noise levels, which may be above permitted levels. Increasingly, noise pollution tends to be a problem adjacent to highly trafficked roadways.

The strategies for noise abatement follow long-established standard procedures in the planning and construction process. Major steps forward have been made to abate noise at the source: the use of special noise-absorbing pavements can reduce it, sound insulating and sound proofing barriers have become more and more efficient, as well as the use of combined features and the deployment of improved construction machines can minimize the generation of noise and vibration (see page on Noise and vibration).

Water impact is another aspect that has to be analysed during the life cycle of an infrastructure such as a tunnel. Detailed investigation of surface and subsurface hydrology should take place before and during construction. The least damaging route and structural elements should be chosen to get minimum interruption and alteration of hydrology patterns and processes. Drying up caused by the manner of building infrastructure is a topic which is becoming more and more important. Several studies can be carried out, which give insight into the effects of infrastructure on the hydrology of areas in the surroundings of tunnels and how to mitigate these effects. Water pollution caused by the leakage of construction materials during worksites can be reduced using containers that are designed to exclude leakage. Once the tunnel is in operation, water pollution caused by the cleaning of the tunnel must be also taken into account (see page on Water impact).

The final objective of tunnel designers and managers is to achieve sustainable operation from both a functional and an environmental point of view, in order deliver a reasonable level of safety and to reduce as far as possible any negative impacts on the environment. Different elements to improve the operational sustainability of tunnels are considered and analysed in technical report 2017R02EN: Road tunnel operations: First steps towards a sustainable approach (see page on Sustainable operation).

Energy consumption is a growing concern for tunnel owners and operators and should be taken into account in the construction phase (by adapting the design to less energy-intensive construction methods) and is essential in the operational phase. Ventilation and lighting systems can notably be optimized and in addition to the environmental benefits reaped, such optimization measures can sometimes lead to non-negligible cost reductions (see page on Sustainable energy consumption).

In the field of road tunnels, air quality is traditionally considered in relation to the level of concentrations of vehicle exhaust inside a tunnel. However, the concentrations of pollutants outside a tunnel can be harmful or annoying to people. Such pollutant concentrations rapidly reduce from a portal or exhaust shaft to the surrounding environment according to complex mechanisms such as the speed and direction of the wind and the neighbouring topography. Consequently, it is recognized that air quality in the vicinity of tunnel portals or other exhaust points is of interest when the traffic intensity increases and when tunnels are constructed in an urban environment.

Above a tunnel, the air quality is expected to be better than if an open air road section was situated at the same location. However at the portals and shafts, polluted air is set free when a longitudinal or transverse airflow is discharged by the piston effect of traffic and/or by ventilation systems.

Depending upon background concentrations and other sources localized close to a tunnel portal or shaft, the concentration levels of pollutants can exceed the maximum levels set by authorities. In that case measures must be taken to improve the air quality in the vicinity of the tunnel. Measures may include civil or mechanical works, planning of the land use around the tunnel, etc. Most often it may be possible reduce the pollution concentrations based on operational measures such as changes in the ventilation regime. Chapter III “Environment” of the 1996 PIARC report 05.02 “Road Tunnels: Emissions, Environment, Ventilation” provided background information on the behaviour of a tunnel air jet from portals.

PIARC has published the Technical Report 2008 R04 "Road Tunnels: A Guide to Optimizing the Air Quality Impact upon the Environment", which focuses on outside air quality related to tunnels and it is a guide to enhancing the urban environment by altering the emissions from vehicles and changing their spatial distribution within the space surrounding a tunnel. The guide considers a wide range of design and operation opportunities to mitigate the impact of tunnels on outside air: from the selection of the most optimum location of a tunnel, to gradients, ventilation type, air discharge management, traffic management, tunnel maintenance and finally (if still useful) contaminant removal techniques (see also Section 4.4.5 "Air cleaning" of the PIARC report 2017 R02 "Road Tunnel Operations: first steps towards a sustainable approach").

The environmental issues linked to ventilation, besides the energy consumption and the related carbon footprint, are linked to the localised, concentrated discharge of polluted air from the portals and stacks. Reducing their impact on the tunnel surroundings is part of good environmental design : see Section 4.3. "Tunnel air dispersion technique", Section 4.6. "Operational aspects" and Appendix D. "Overview of dispersion modeling in designing ventilation systems" of the PIARC report 2008 R04 "Road Tunnels: A Guide to Optimizing the Air Quality Impact upon the Environment".

Additional information specific for complex tunnels can be found in section 8.1 "External Air Quality" of the PIARC Report 2016 R19 “Road Tunnels: Complex Underground Road Networks”.

Noise is generally regarded as one of the key nuisances perceived by humans, which can significantly affect urban areas. It should therefore be taken into account in the design of tunnels, especially for those urban tunnels that have a high concentration of acoustical receptors in the immediate vicinity of portals and shafts.

Traffic-generated noise is not specific to tunnels. Underground infrastructures are generally regarded as having a positive influence on the acoustic environment, but there might be specific issues near the portals in some configurations. In most developed countries, noise impact studies are performed for every new infrastructure project (or significant modification), and the existence of tunnels is, of course, to be taken into consideration.

Figure1: Example of a noise barrier above a tunnel portal in an urban area

There are also sources of noise that are associated with the tunnel infrastructure, the main one of which is the ventilation system. In the case of transverse ventilation, or longitudinal ventilation with extraction shafts, fans and air flow through inlets and outlets may generate significant noise, and in some cases they have to function even at night time when noise environmental standards are set at lower targets. One solution may be to reduce the use of the ventilation system by optimising its control, but this can only be achieved to a limited extent.

The most effective solution is to take these problems into account at the design stage. Considering that the most prominent noise effects are geographically limited, air inlets/outlets may be located as far away as possible from neighbouring buildings, but this may result in significant increases in cost. The air velocity should be kept at relatively low values at air inlets/outlets to reduce noise generation by making the size of these openings large enough. Additionally, silencers are most often necessary to prevent the noise generated by the fans from "leaking" out of the ventilation plant.

In the case of longitudinal ventilation, the noise impact from fans on the environment is generally moderate because, on the one hand, jet fans should not be located too close to the portals for maximum efficiency (consequently the noise of fans is "diluted" within the traffic noise), and on the other hand, silencers are usually fitted to the fans to maintain an acceptable noise level inside the tunnel. However, for particularly sensitive configurations, it might be necessary to select specific designs or operational measures.

Traffic-generated vibration is rarely a significant issue in the operation phase of a road tunnel (unlike rail tunnels, because trains generate much more vibration than road vehicles). Should such a problem occur, there is generally little that can be done apart from prohibiting access to the heaviest vehicles. Another source of vibration is the fans. These should be carefully balanced to avoid excessive vibration. However, fan vibration is generally not perceivable in the environment; it primarily affects the machine itself, and can compromise its longevity. It can also become a safety issue because jet fans, for example, may lose parts or even fall down from the tunnel ceiling due to excessive vibration. Vibration monitoring is crucial for the reliability and safety of jet fans.

Vibration is much more problematic during the construction phase, especially when explosives are used. Tunnel construction and related environmental measures are outside the scope of the PIARC committee on road tunnel operation; specific recommendations are published by the ITA.

The impact of road infrastructure on water quality can be very significant during both normal operation (leaking of hydrocarbon products, tyre wear, etc.) and accidental situations (spilling of large quantities of pollutants).

The existence of a tunnel does not change the problem very much. As on any road, there is a need for water treatment (decanting, removal of pollutants) before releasing it into the environment. A few tunnel-specific facts should however be taken into account when designing water management systems. First, tunnels need to be cleaned on a regular basis, as often as every month for heavily trafficked urban tunnels. This generates large amounts of waste water containing cleaning products. Second, tunnels in which dangerous goods transports are allowed are generally equipped with specific gutters in order to limit the spread of flammable liquids on the pavement. If an accidental spill occurs, the flow rate of pollutant liquid in these gutters may be higher than what is encountered on a regular road surface, and the water management system should be capable of coping with these flow rates.

Very challenging issues related to water may be encountered during the construction phase in sensitive environments, for example regarding the turbidity of the construction site effluent. Appropriate measures should then be taken. In some cases, they represent significant constraints and cost for the construction works. Tunnel construction and related issues are outside the scope of the PIARC committee dedicated to road tunnel operation. The reader is therefore encouraged to consult ITA recommendations for further details.

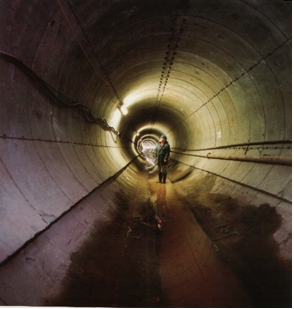

Fig. 1 : Water ingress in a tunnel built with segments

Water impact is another aspect that has to be analysed during the life cycle of an infrastructure as tunnel.

Most of the impact of tunnels on water (and water on tunnels) happens during their construction, but some of the impacts remain for a long time and can become a hindrance to the tunnel operation and maintenance. Due attention must be given to these processes during the tunnel planning and design stages, in order to avoid adverse, and costly, consequences. Detailed investigation of surface and subsurface hydrology should take place before and during construction. The least damaging route (and structural elements) should be chosen to obtain minimum interruption and alteration of hydrological patterns and processes.

Theoretically, tunnels can be: impermeable (allowing no ingress of water and developing the full water pressure on the lining), permeable or semi-permeable (allowing some ingress of water and avoiding the development of full water pressure on the lining). In practice most tunnels are permeable during their construction and impermeable or semi-permeable during their operation. As a general rule water ingress into road tunnels are normally not accepted as it may have severe impact on the tunnel structure and in special cases can cause severe deformations, displacements, settlements and unwanted stresses leading to deterioration and in worst case collapse of tunnel walls and ceiling (bursting and squeezing of bare rock as well). For mechanical and electrical installations it may impact their functionality and lifetime expectation.

Fig. 2 : Water flowing through a permeable basalt layer

Minor water ingress is tolerated if it can be completely controlled. This covers tunnels located in specific rural areas and with extremely low traffic. This has been done in several locations in the period 1970 to 2000. In recent years, rock tunnels have been constructed a with semi- or full inner-lining due to experience with tunnel collapses etc.. As a general rule (see national and international standards, codes etc.), all tunnels nowadays are designed with waterproofing systems to be delivered as completely waterproofed tunnels.

In unlined tunnels (or with a permeable lining), water ingress can be important. Fig. 2 shows water flowing through a permeable basalt layer in Canada.

The drying up of groundwater levels caused by the manner of building infrastructure is a topic which is becoming more and more important. The effect usually does not finish during tunnel operation, and the groundwater original levels almost invariably go down, with an irreversible impact on water supply wells.

The water entering a tunnel can dissolve the free lime hydroxide in the concrete lining, becoming more alkaline and releasing solid deposits in the drainage systems. This effect is more frequent in old tunnels with out-dated drainage systems. Fig. 3 shows drainage water flowing and lime calcium hydroxyls precipitating in a concrete lined tunnel. Fig. 4 shows a similar effect in a construction joint.

Fig. 3 : Drainage water flowing and lime calcium hydroxyls precipitating in concrete lined tunnel () Fig. 4 : Similar effect in a construction joint ()

Figure 1: Croix Rousse tunnel (Lyon, France), which has a tube dedicated to buses and environmentally-friendly modes of transport

Throughout its history, PIARC has published several reports aimed at improving the efficiency of tunnel operations, reducing operating costs and mitigating environmental impacts.

With the world population increasing, and several natural resources running scarce, sustainable development has justifiably become a topic of interest in various domains of society over the past decades. The field of infrastructure is no exception.

However, within this field, there are few guidelines and best practices available that specifically address the sustainability of road tunnels.

Moreover, so far, the World Road Association has not issued any recommendations for road tunnels which reflect the current ‘state of play’ in various countries. This is understandable, as road tunnels are just a small part of the road network as a whole. On the other hand, given that road tunnels are complex and expensive objects, with a life cycle that normally spans more than 100 years, it is clear that the concept of sustainable road tunnel operation is of great relevance.

The technical report 2017R02EN "Road tunnel operations: first steps towards a sustainable approach" was therefore developed as an initial means of making up for this shortfall.

Optimizing the operating costs of a tunnel and in particular those related to energy consumption, is a task that must be undertaken from the early stages of the tunnel design. PIARC has shown that a significant part of operating costs is determined by the choices made during the design and implementation phases (Report 05.13.B Good practice for the operation and maintenance of road tunnels).

It is also important to adopt a global approach that takes into consideration the three pillars of sustainable development: societal, environment and economic (report 2017R02EN: Road tunnel operations: First steps towards a sustainable approach). More specifically, it is important to avoid implementing a solution that is advantageous in terms of initial investment, but which entails an excessive annual energy consumption.

This naturally leads to applying an approach based on the cost of tunnel ownership as a whole, taking into account not only the initial cost of equipment, but also operating costs throughout the tunnel’s expected lifetime (Report 2016R01EN Best practice for life cycle analysis for tunnel equipment).

As the equipment present in tunnels is numerous, diverse and has lifespans that vary considerably from one type to another, it is often more efficient to conduct a specific optimization approach for each large family of equipment.

Finally, although, as we have said, the optimization work must be started during the initial design phases, the technical provisions chosen and the equipment implemented require constant monitoring, if they are to maintain their performances over time. Regular and thorough maintenance is therefore necessary so that all the actions undertaken to optimize the energy consumption of a tunnel remain efficient (Report 05.13.B Good practice for the operation and maintenance of road tunnels).